|

|

||

|

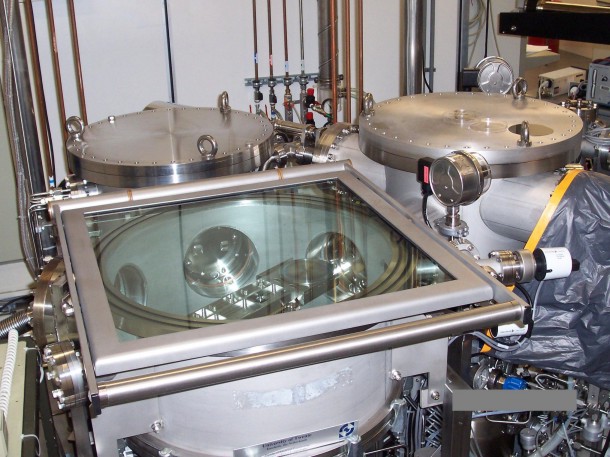

FUTURE: mini environments, cluster tools. Because the cleanroom is much larger than the wafers and very expensive to maintain, the idea of minimizing the cleanroom volume has appeared. The cluster tools consist of several small reactors connected through tubes, big enough for the wafer to pass (see picture below). The transport from chamber to chamber is automatically done by robot arms (one robot arm can be seen in the loadlock with transparent lid below). The chambers are maintained at low pressure (i.e. low contamination) and vacuum is not broken between the processing steps. Cleaning, deposition of several types of materials, doping, annealing are all realised in one cluster tool in different reactors (in the picture below 2 reactors can be seen behind the loadlock). Thus, only the small processing chambers have to be cleaned (vaccuum is created by pumping out the air ). Another major advantage besides the cost is the low contaminants concentration in vacuum, which is not broken. Another advantage is the fact that you can introduce all the gases lines in the cluster, giving more freedom in choosing the gases needed for the device fabrication. The disadvantage will be the fact that you cannot work in the same time with more than one reactor in the cluster. Therefore it is not very efficient for industry, only for research, by reducing the total costs.

|

Substrate preparation

Substrate preparation