|

|

||

|

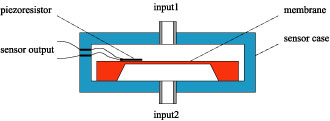

Basic arrangement of a pressure sensor

Differential pressure measurement - between input1 and input2, Gauge pressure measurement - if the input2 is closed under the atmospheric pressure conditions, Absolute pressure measurement - when the input2 is vacuum sealed. Sensor fundamental part - plate (membrane) of silicon or polysilicon equipped with one or several piezoresistives gauges.

The pressure difference induces a stress variation in the plate. The resulting stress is then measured by piezoresistive gauges that are placed in specific places of a plate. Piezoresistors can be diffused in silicon plates with different crystal orientations, along many crystal directions. In order to make an optimal choice of a piezoresistive sensor location, the stress pattern on the surface of the plate deformed by the pressure difference should be known. Typical geometrical forms of the sensor membrane

|

Accelerometer

Accelerometer