Microsystems Technology (MST) is a process technology used to create tiny integrated devices or systems that combine mechanical and electrical components. This technology offers many exciting opportunities in miniaturization of elements in a wide range of applications. The technology using integrated circuit (IC) batch processing techniques is referred to as Microsystems Technology (MST) in Europe, Micro-Electro-Mechanical Systems (MEMS) in the United States, and Micromachines in Japan. Regardless of terminology, the uniting factor of a micro-device is in the way it is made. Micromachining processes such as bulk and surface micromachining, as well as high-aspect-ratio micromachining (HARM) selectively remove parts of the silicon or add additional structural layers to form the mechanical and electromechanical components.

Microsystem devices have the ability to sense, control and actuate on the micro scale, and generate effects on the macro scale. The silicon pressure microsensor used presently in millions of automobiles is the best-known application of microsystem technology. Micromachined accelerometers are used for triggering air bags and controlling active suspensions and anti-skid brakes. Microactuators are following the success of microsensors. Perhaps the first major commercial application of actuators has been in camera objectives introduced by Canon in 1987. In addition to consumer electronics and automotive industry, microsystems are used in communications technology, chemical and environmental analysis, life science, medical technology and process industry, even in paper making.

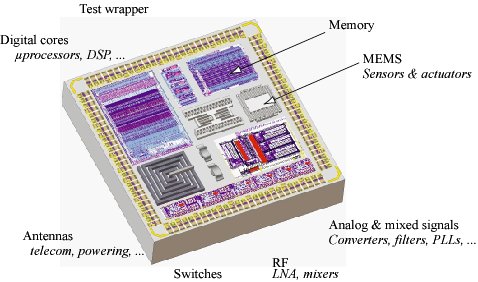

In the most general form, microsystems consist of mechanical microstructures, microsensors, microactuators and microelectronics, all integrated onto the same silicon chip as shown schematically in the following figure:

There are many advantages of microsystems devices over current devices that perform the same functions:

- Substantially smaller size of microsystems comparring to macro-devices that perform the same function.

- Integration of the electronic and microsensor components in the same device improving the precision and sensitivity of sensors.

- Less expensive production by a batch fabrication using IC processes.

The diversity and complexity of the micromachining technology demands a wide knowledge base from a prospect researcher. The goal of this course is to provide the student the needed expertise to approach the development of microsystem devices. |