|

|

||

|

Screen Printing: the characteristic layer deposition and patterning process of thick-film circuits

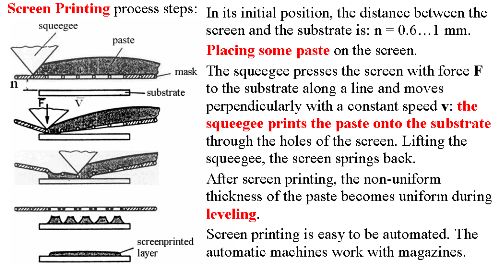

The principal steps of thick film technology are screen printing of pastes onto ceramic substrates and - after leveling and drying - firing them at a temperature between 500 and 1000 deg C. The various layers are deposited by screen printing – or sometimes by other printing techniques – usually onto ceramic substrates, using special pastes or inks, which – after a subsequent settling for leveling; drying; and firing processes – form the layers of the integrated elements of required parameters. In the screen printing process the screen mask (stencil screen) defines the layer pattern. The screen is a woven mesh material made of stainless steel or plastic fiber. The screen mask is the screen with polymer (gelatin, called emulsion) or metal coating that fills unnecessary openings of the screen, thus results in a mask with well-defined windows (openings). The screen mask is stretched out by the screen frame that is made from metal, generally from aluminum. The frame with the screen mask is positioned parallel to the substrate, with a usual distance of 0.6 - After placing the necessary amount of paste onto the screen, the squeegee presses the screen mask to the substrate and - traveling along the screen - prints the paste onto the substrate through the openings of the screen mask. Although the printed layer thickness is principally governed by the mesh count and the rheological characteristics (e.g. the viscosity) of the paste, the following technological parameters have also influence on the reproduction: - the screen-to-substrate distance (0.35 - - the line pressure of the squeegee (ca 2 N/cm), and its angular positions, - velocity of the squeegee, i.e. the printing speed (5 - 20 cm/s), - elasticity of the screen, depending on the dimensions and the tension. The screen printing process

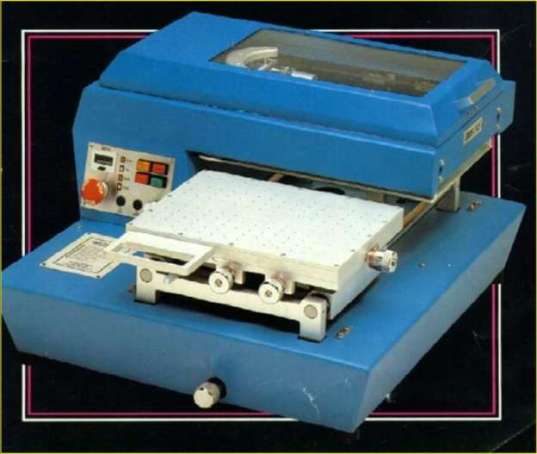

The screen printing process applies semi-automatic or automatic equipment in which the above mentioned technological parameters are adjustable. The yield of these printers reaches some thousand circuits per hour value. A printer for screen printing of thick films

Let's play the printing process

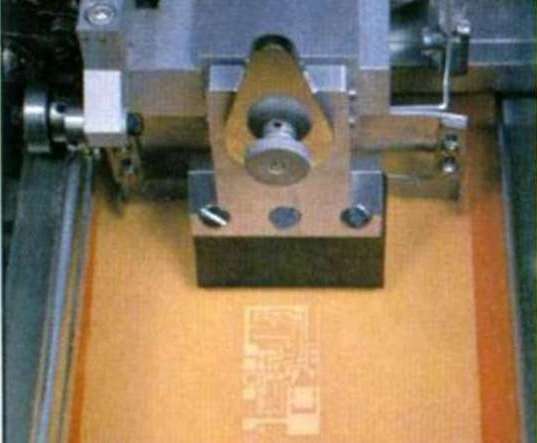

The tools of screen printing: the squeegee over the screen mask

|

Screen Printing

Screen Printing