|

|

||

|

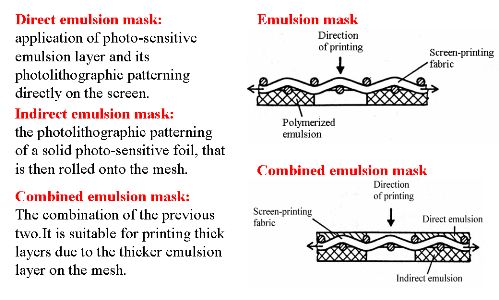

Types of screen masks (1): emulsion masks

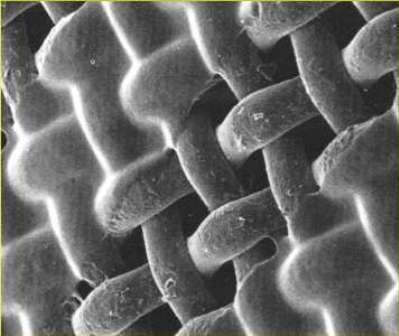

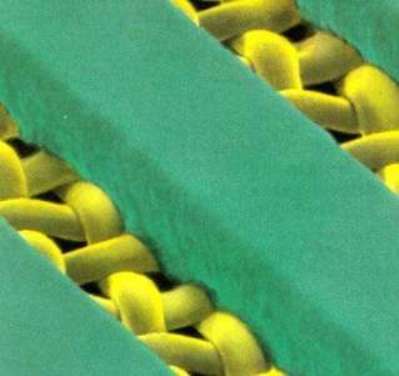

Screen masks (stencil screens) are used in thick film technology to define the pattern of the various layers deposited by screen printing onto ceramic substrates using pastes. The screen mask has well-defined windows in the screen: the unnecessary openings of the screen are filled by polymer emulsion or metal coating, when the screen mask is fabricated. Emulsion masks use photosensitive polymer coating deposited by sol-gel technology or laminated and rolled as foil onto the screen. The layer of the sol-gel type emulsion is patterned on the screen, while the pattern of foil type emulsion is prepared before lamination by photolithographic processing. The thickness of the emulsion layer is critical, since - together with the thickness of the screen defined by the mesh count - mostly it determines the thickness of the printed thick film. Photos of emulsion type screen masks

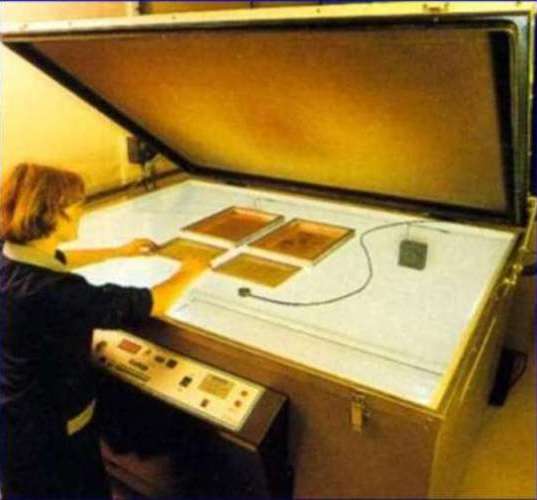

Fabrication of emulsion type screen masks

|

Screen Printing

Screen Printing