|

|

||

|

The types of screen masks (2): metal masks

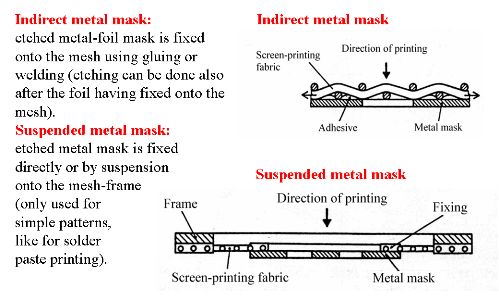

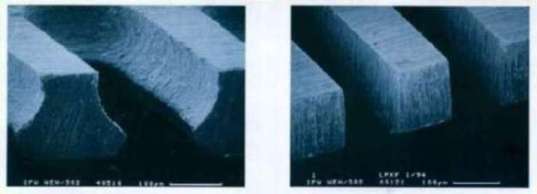

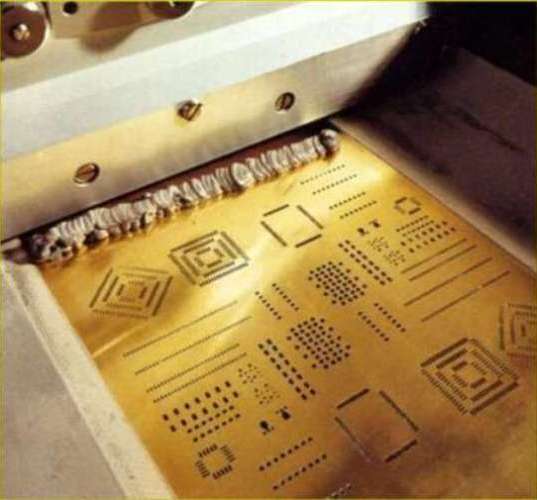

For the preparation of layers in a thicker range, screen masks with metal masking coatings are also in use. In this case it is mostly the thick metal foils, which determine the thickness of the resulting layer. For very simple patterns, e.g. for solder layers where the requested openings are squares or rectangles, the screen can be omitted, and the metal mask is used for printing the pattern. In this case the mask is called stencil or stencil mask. The reason of the application of the screen for more complex patterns is to fix the bendable narrow and long parts of the masking coating. The windows of the stencil are fabricated either by photolithography and etching or by laser cutting. Cross-sections of the opening of stencil masks

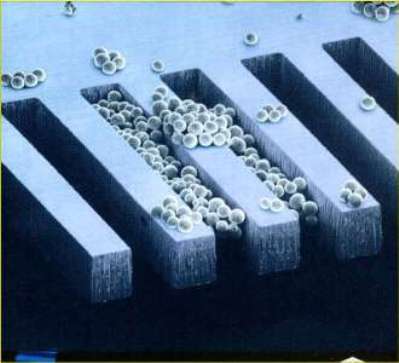

Metal masks and stencil screens are used in thick film technology when thicker layer deposits of simple patterns are requested, therefore stencil masks are applied for screen printing of solder paste layers. Solder paste printing using stencil mask

Cross-section of a stencil masks with solder paste residues

|

Screen Printing

Screen Printing