|

|

||

|

Computer

controlled laser systems are used in mass production for the

automated trimming of thick film resistor elements. Current technique

uses a pulsed laser beam to notch the resistors. Resistance values can only be

increased, in other words, the layout must be designed that all resistances

before trimming - taking into consideration of the manufacturing dispersion of

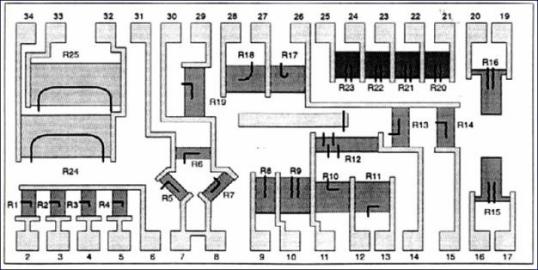

the values - should be below their nominal values. Laser

trimming strategy for the resistors of a thick film

circuit

A

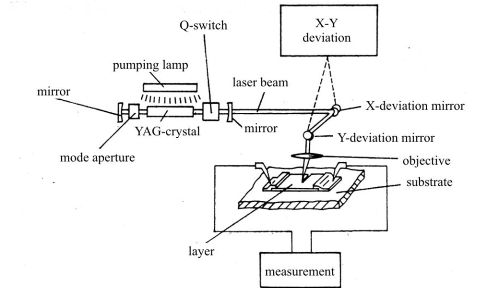

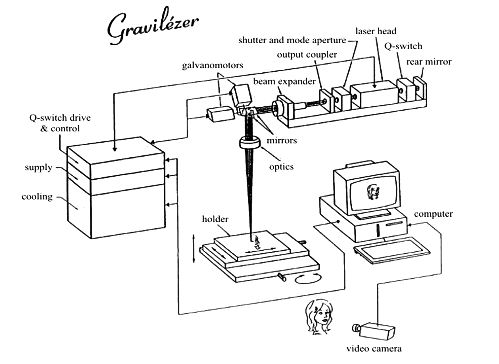

laser trimming systems consists of the following main

parts: -

the laser, or laser head, including

the most popular Nd:YAG laser crystal, the pumping source, the Q-switch and the

beam shaping optics; -

beam delivery system, usually using

rotating mirrors driven by galvanomotors, and/or X-Y

stages; -

flat-field optics, to focus the

rotating beam to the flat substrate; -

probing system, to make the proper

connections between the measuring bridge and the actually trimmed resistor,

either by using a multi-probe frame or a pair of flying probes;

-

bridge type measuring system;

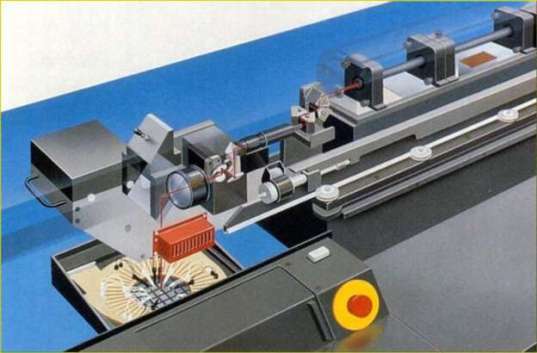

- a control computer. A

laser trimmer

A

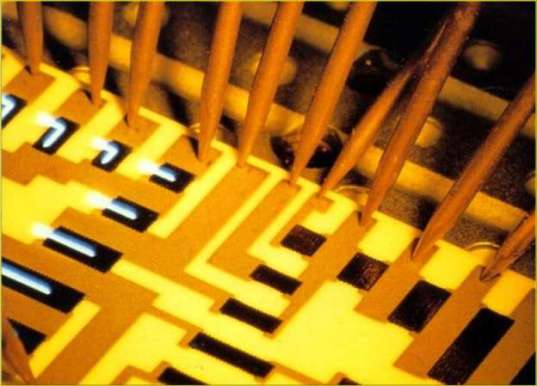

circuit under the probes of a laser trimming system

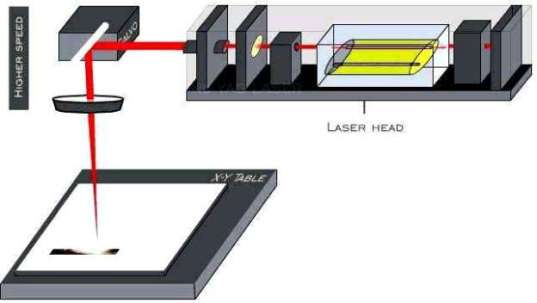

Laser

system for trimming and marking

In

addition to resistor trimming, computer controlled laser systems are applied in the

technology of thick film hybrid circuits for the separation of the substrates, for

marking, soldering, welding, etc. The

parts of a laser marking system

A trimming system in operation

|

Screen Printing

Screen Printing