|

|

||

|

Trimming technologies, laser trimming

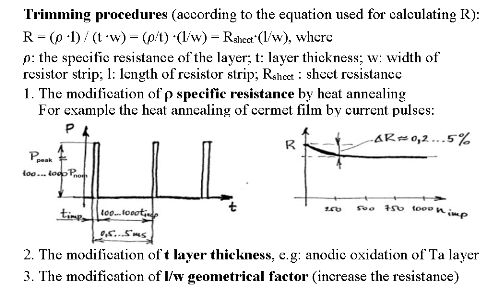

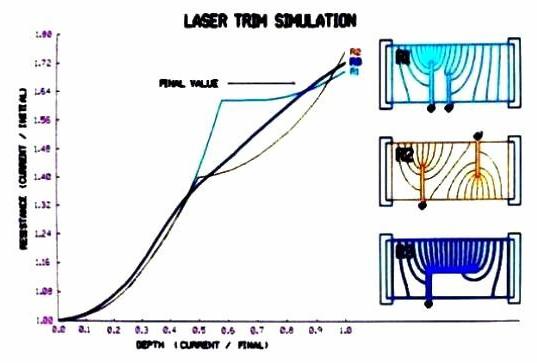

Trimming is the process when the value of a resistor (sometimes a capacitor or another component) is adjusted in order to get much more accurate value of the component or achieve better performance of the circuit. In accordance with the basic equation for the calculation of the resistance R = r*l/(t*w) = r*l/w, trimming can be carried out by changing one or more of the following parameters: - specific resistance (r): heating usually causes resistance decrease because of resulting in a more regular structure, while it can also increase the resistance as a result of oxidation; - thickness of the resistive path (t), which can be precisely decreased by anodic oxidation in the case of some special materials like tantalum, finally resulting in the increase of the resistance; - aspect ratio (length/width = l/w) of the resistor, by machining kerfs in the layer, thus ‘notching’ a resistor and raising its nominal resistance with the use of a laser beam. Computer simulation of the effect of laser trimming

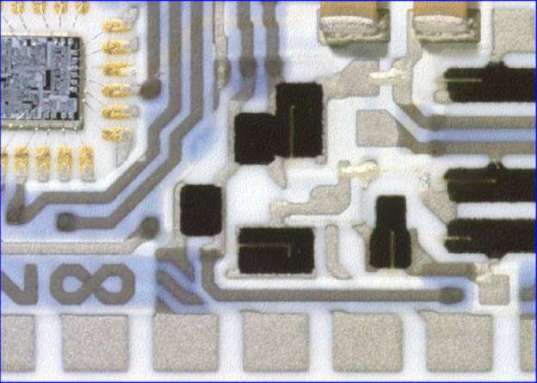

Laser trimmed resistors on a thick film hybrid circuit

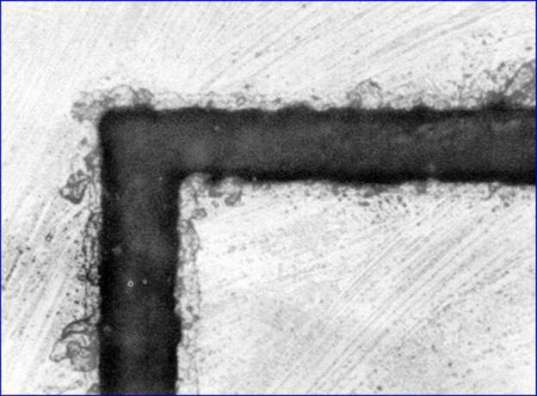

Laser machined kerf in a thick film resistor

|

Screen Printing

Screen Printing